How Thick Should a Concrete Driveway Be?

How Thick Should a Concrete Driveway Be? The Ultimate Guide for Homeowners

When you are planning to make a new driveway, one of the most important decisions you'll make is how thick the concrete should be. It's not just about pouring some cement and calling it a day. If the concrete driveway thickness is too thin, it can lead to serious problems down the road. Cracks, sinking, and surface wear can start to show up much sooner than expected.

What is the Standard Concrete Driveway thickness?

- One design for your desktop, tab and mobile.

- Beautiful and modern design that makes difference.

- Boost your sales with strategically built user experience.

When You Need More Than 4 Inches

Every driveway is not the same, and that 4-inch rule doesn’t work for everyone. If you plan to park heavier vehicles like RVs, trailers, or commercial vans, you’ll likely need something more robust. In these cases, bumping up to 5 or even 6 inches of concrete can make a big difference in how well your driveway holds up over time.

How Much Weight Can a Driveway Hold?

You might also be asking, how much weight can a driveway hold? Well, 4 inches of concrete, when poured over a solid, compacted base, can typically handle up to 8,000 to 10,000 pounds. The overall strength of your driveway depends not just on materials, but also on the proper cement thickness for driveway, the quality of the subbase, and whether reinforcement like rebar or mesh is included.

Commercial Driveways Require Extra Strength

For commercial driveways or areas with frequent heavy vehicle traffic, a concrete thickness of 6 to 8 inches or more is usually recommended. This added depth provides the strength needed to handle larger loads without premature damage.

Digital Agency

Market Analysis

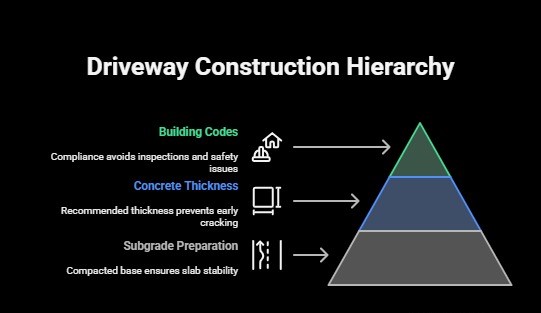

Don’t Forget Local Building Codes

Another thing to keep in mind is that local building codes can influence what’s required. Some cities or counties may have specific rules about standard concrete slab thickness or reinforcement for driveways, especially in areas with heavy snowfall or poor soil conditions. It’s always a smart move to check in with your local building department or consult a contractor familiar with your area.

Factors Influencing Driveway Thickness

When it comes to how thick your driveway should be, there’s no one-size-fits-all answer. Several factors play a big role in determining the right cement thickness for driveway projects. It’s not just about the concrete itself. Let’s break down the key things that can affect your driveway’s durability and design.

a. Soil Conditions and Subgrade Preparation

Before the concrete is even poured, what’s underneath it matters a lot. The type of soil your driveway sits on, whether it’s clay, sand, or loam. It can make a big difference in long-term stability. For example, clay soils expand and contract with moisture, which can lead to shifting and cracks if the driveway isn’t built with that in mind.

That’s why having a well-compacted subgrade is crucial. A strong, level base helps distribute weight evenly and prevents your concrete from settling or cracking over time. If the soil beneath the driveway is too loose or not compacted properly, even using the right cement thickness for a driveway won’t be enough to prevent future cracks or sinking.

b. Climate and Environmental Considerations

If you live in an area where winters are cold and snow is common, freeze-thaw cycles are a real concern. Water can seep into tiny cracks or gaps, freeze, and then expand, leading to even bigger cracks or surface damage. Choosing the right concrete thickness for garage floors or driveways helps protect against these kinds of weather-related issues.

Good drainage is another thing that’s often overlooked. If water collects on or under your driveway, it weakens the concrete over time. Sloping the surface slightly and installing proper run-off systems can go a long way toward extending your driveway’s life.

c. Local Building Codes and Regulations

Every city or county may have different rules about how to build a driveway. These rules often cover everything from rebar spacing for driveway reinforcement to minimum concrete sidewalk thickness and even the width of a standard driveway.

For example, your area might require permits or inspections before you start building. Some places also set guidelines for the average driveway width to make sure there’s enough space for safe access. Following these local codes doesn’t just keep things legal—it ensures your driveway is built to handle local soil, climate, and traffic conditions.

Why Steel Reinforcement Matters in Concrete Driveways

Concrete driveways are an investment, and how long they last depends on more than just the thickness. The materials used, how the concrete is placed, and even the surface treatment all play a part in making sure your driveway holds up over time.

a. Reinforcement Options

One of the most effective ways to improve durability is by reinforcing the concrete. Steel rebar or wire mesh is often placed inside the slab to give it more strength and reduce cracking. These materials help distribute the load more evenly and support the concrete where it’s most likely to fail, under tension. When using rebar, it’s important to get the rebar spacing for the driveway just right. A typical spacing might range from 12 to 18 inches, depending on the driveway’s thickness and expected vehicle load.

Another option gaining popularity is fiber-reinforced concrete. This type of mix includes tiny synthetic fibers spread throughout the concrete. While it’s not a full substitute for steel reinforcement in heavy-load areas, it’s a great way to increase resistance to surface cracking and shrinkage in residential driveways.

b. Proper Joint Placement

Even with reinforcement, concrete will expand and contract as temperatures change. That’s why proper joint placement is key.

Control joints are planned cuts in the slab that allow the concrete to crack in a straight line, rather than randomly across the surface. They’re usually spaced every 8 to 10 feet and help keep the driveway looking clean and structurally sound.

Expansion joints are placed between the driveway and any adjoining structure like a garage floor or sidewalk. They provide room for the concrete to expand and shift without causing damage.

c. Surface Treatments

Once the concrete has cured, finishing touches can also add to its durability. Applying a high-quality sealant helps protect against water, oil, salt, and harsh chemicals. This is especially useful in areas that see freezing temperatures or lots of road salt during winter.

Textured or brushed finishes can improve slip resistance, making the driveway safer during rain or snow. These simple steps add years of life to your driveway and reduce long-term maintenance needs.

Cost vs. Benefit: Though it increases upfront cost, the extended lifespan and reduced maintenance often offset the investment.

Common Mistakes to Avoid

Cutting corners on concrete thickness: Trying to save money by pouring less concrete may lead to early cracking and costly repairs. Always stick to the recommended cement thickness for driveway based on your vehicle load.

Skipping proper subgrade preparation: Even the best concrete won’t last if the ground below is soft or uneven. A poorly compacted base weakens the slab, no matter the concrete driveway thickness.

Ignoring local building codes: Every area has its own rules, some even dictate rebar spacing for driveway or minimum slab depth. Overlooking these can cause failed inspections or safety issues later on.

Maintenance Tips for Longevity

Check regularly for small cracks or surface damage: Even with the right concrete thickness, small cracks can form over time. Catching them early helps prevent bigger issues later.

Seal your driveway every few years: A good sealant protects against moisture, oil stains, and weather, especially important if your cement is exposed to freeze-thaw cycles.

Keep it clean: Regularly removing dirt, leaves, and chemicals helps maintain the finish and slows down surface wear, no matter the width of a standard driveway or material used.

Conclusion

Choosing the right concrete thickness for your driveway isn’t just fulfilling the numbers. It’s about protecting your investment. The right depth combined with proper base preparation and reinforcement always helps your driveway last longer and handle everyday use without problems. If you’re unsure what works best for your home you can talk to a local concrete expert. They can assess your soil, climate, and traffic needs to recommend the ideal solution.

Frequently Asked Questions

With the right thickness, reinforcement, and maintenance, a concrete driveway can last 25 to 30 years or more. Sealing it every few years and fixing small cracks early will help extend its life.